Japanese knives are widely regarded as a foundation of high performance cutlery. If you’re a home cook or a professional chef, you know that steel composition and blade geometry are more important than branding when buying a knife. Finding the right Japanese knife is about matching function, hardness, toughness, and maintenance expectations to real kitchen loads.

To help you make an informed decision, let’s break down the 10 best types of Japanese knives, explaining what each one is designed for and what to consider when buying a Japanese knife.

How to Choose the Right Japanese Knife for Your Kitchen

Buying Japanese knives is not about choosing the one that everyone else likes. It is about getting one that has the right steel, geometry, and construction for your work style and skill level. Here’s what to consider before purchasing a Japanese knife:

- Primary use case: First, think about what you’ll be using the knife for. Vegetable cutting, meat slicing or boning, and fish cutting require distinct knives.

- Steel type and hardness (HRC): Harder steels (from 62-65 HRC) have more edge retention, but with lower toughness. Softer steels in the range of 58 – 60 HRC on average are more recommended to mixed use or if you share your kitchen.

- Blade geometry and thickness: Thin edges improve cutting performance but increase fragility. Thicker spines provide stability at the cost of precision.

- Maintenance requirements: Carbon steel knives require proactive rust prevention (but are easy to sharpen). Stainless and powder steels could require less maintenance but are more difficult to get as sharp as carbon knives

- Handle ergonomics and balance: The shape, material, and balance point of the handle influence how well you can control it and how much fatigue you feel during a long prep session. Test grip comfort before committing.

List of Top 10 Japanese Knives and How to Use Them

Now, let’s discuss the best types of Japanese kitchen knives you’ll need for different purposes. But remember – selecting the right type is only half the decision; you need to buy Japanese knives from a reputable maker to ensure proper heat treatment, verified steel composition, and consistent quality control.

1. Gyuto

Best for: General slicing, chopping, and preparation of meats

Gyuto is Japan’s native equivalent to a Western chef’s knife and the workhorse of any professional kitchen. These knives are mostly used for vegetables, boneless meats, and general ingredient prep.

The majority of Gyuto knives are constructed with VG10 or AUS 10 Damascus stainless steel and range in hardness from 58 HRC to 61 HRC. VG10 holds an edge longer while AUS 10 is tougher and sharpens more easily. This balance is the reason most professionals choose a Gyuto knife for everyday use.

2. Santoku

Best for: Fine slicing and veg-centric prep

Santoku knives are shorter and flatter than Gyuto knives, making “push cut” slicing a better technique for them. They are very good for vegetables, boneless meat, and thin slicing.

High end Santoku knives usually have a heat treatment to 60 HRC and above, which ensures excellent cutting properties whilst still being tough enough for daily prep. Santoku is a strong choice if you like to feel in control and keep things tidy.

3. Nakiri

Best for: Especially for cutting, slicing, and chopping vegetables

The Nakiri is a straight-edged, flat, thin, and tall vegetable knife designed for clean, vertical chopping. The squared tip of Nakiri knives, like Takahiro Nakiri, allows accurate scoring, mincing, and julienning without rocking.

Since Nakiri knives are subjected to minimal lateral stress, they generally are made with harder steel with 62+ HRC to extend edge retention. Need to prepare a large amount of vegetables? A Nakiri will always be your first choice!

4. Yanagiba

Best for: Prepping sashimi and slicing raw fish

Yanagiba knives are long, single bevel slicers for clean, one-draw cuts through fish. This avoids damage to the cells and leaves the texture intact.

These knives are commonly forged from white or blue carbon steel, hardened between 60 and 64 HRC. You gain exceptional sharpness but must accept higher maintenance due to corrosion sensitivity.

5. Deba

Best for: Fish butchery and filleting

The Deba is thick spined and heavy, built to remove fish heads and break down whole fish. It prioritises toughness over extreme sharpness.

Most Deba knives use Aogami (blue steel) or Shirogami (white steel), where a hard core is protected by softer outer layers. This reduces the risk of chipping when encountering bones.

6. Usuba

Best for: Advanced vegetable techniques

Professional grade single bevel vegetable cleavers, Usuba knives are ideal for precision work such as katsuramuki and ultra thin slicing.

They are often hardened to 62 HRC or higher, providing a very thin edge. This leads to excellent cutting performance but does require careful use to prevent chipping.

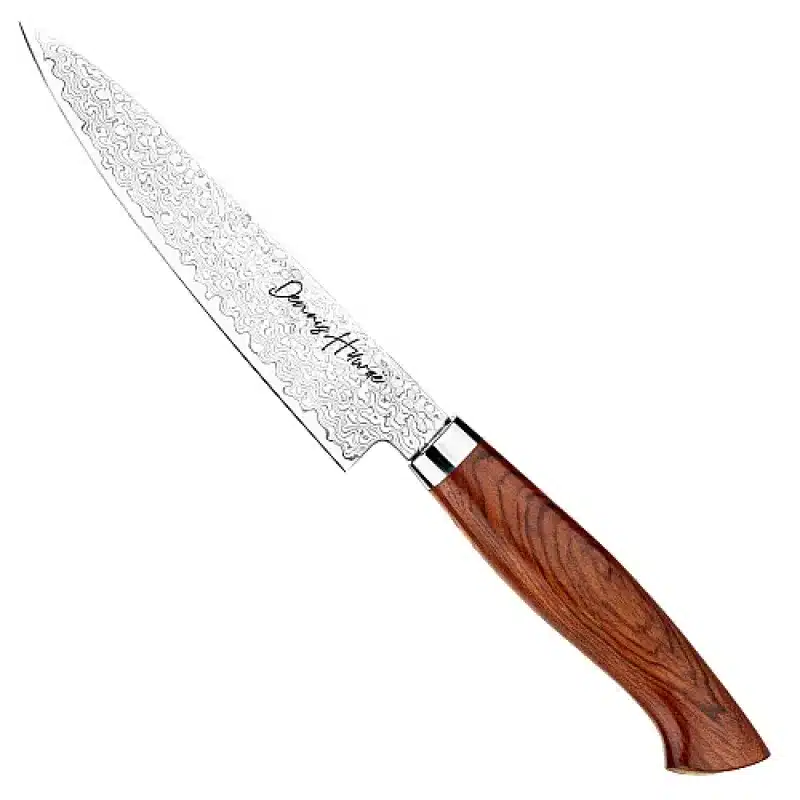

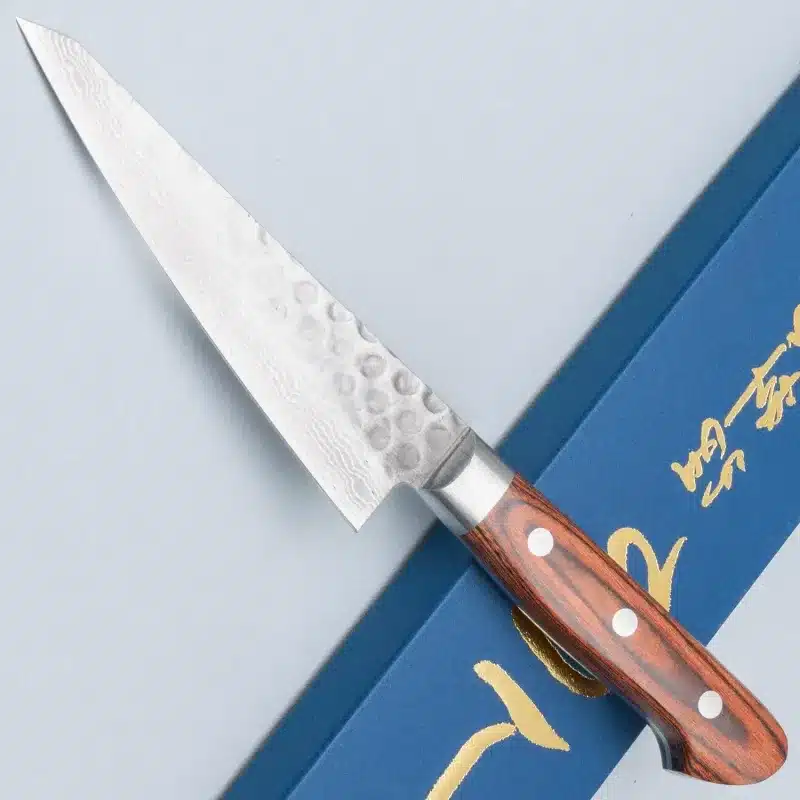

7. Petty

Best for: Utility and detail work

The Petty knife bridges the gap between a paring knife and a chef’s knife. Perfect for trimming, peeling and intricate cuts when a larger blade is more than you need.

Tough stainless steel like VG10 or AUS 10 at HRCs between 58 and 61 makes a perfect balance between strength, durability, and edge life.

8. Kiritsuke

Best for: Skilled users needing a hybrid blade

Kiritsuke knives combine features of Gyuto and Yanagiba blades. They are long, angular, and demand precise technique.

For professional users, laminated carbon steel or powder steels hardened to 62 HRC or higher deliver long lasting sharpness, particularly for vegetable and protein slicing.

9. Honesuki

Best for: Poultry breakdown

The Honesuki is a stiff, triangular boning knife designed for breaking down poultry. It excels at joint separation and cartilage work.

Toughness is critical here. Slightly lower hardness levels help prevent edge failure during heavy tasks.

10. Sujihiki

Best for: Long slicing of roasts and fish

The Sujihiki is a double bevel slicer designed for clean, single stroke cuts through large proteins.

High end versions often use SG2 or R2 powder metallurgy steel, hardened up to 64 HRC. These steels offer exceptional edge retention but require disciplined technique to avoid microchipping.

Understanding Steel Trade Offs

Typically, Japanese kitchen knives are about 58-65 HRC, depending upon steel types and the target (or specific) use of the knife.

- Higher hardness increases edge retention

- Lower hardness increases strength and improves toughness and impact-resistance.

VG10 tends to be on the 60-61 HRC range while steel powders or compositions like SG2 well exceed 63 HRC. Carbon steels like Aogami Super can reach upto 65 HRC but need more maintenance.

A few technical characteristics are sometimes published, typically through steel manufacturer datasheets or independent metallurgy testing reports. When available, use these values to assess a blade’s resistance to chipping and cracking under high stress conditions.

Final Thoughts

There’s no one knife that can do every kitchen job well. Ultimately, the right purchase path is to select knives for the designated role and match the steel type and hardness to that application.

When edge retention is what matters, powder metallurgy steels at higher HRC get you there. But when it comes to durability and forgiveness, using slightly softer or layered blades is more acceptable to reduce risk. Make certain to get all specs in the documentation before you buy Japanese knives.